What is the major difference between vodka and other spirits? While traditional vodka is prized for its clean taste through the extensive use of filtration and distillation, spirits such as bourbon or cognac have a characteristic complexity in flavor. According to some, 60% to 70% of this flavor complexity is solely derived from prolonged storage in a cask1. Ranging from the preparation of the wood for the barrels up to the final product, this process can span decades and is chock-full with a plethora of chemical processes. Breaking with tradition and understanding the complexity behind these processes allows us to further push this boundary of flavor.

Before we can store our freshly distilled spirit in a cask, we first have to build it. For this, the choice of wood is paramount. In most countries, the vast majority of barrel-aged spirits are produced with oak barrels2. Yet even here there are large differences: Quercus alba (white oak) is mostly used for American and Canadian barrels whereas Quercus robur (English oak) is predominantly used in Europe3. A different wood density (white oak being denser than English oak) leads to less leakage and evaporation but also to a slower maturation of the contained spirit for barrels made from white oak4. English oak also has a lot more tannins (most noticeably gallic acid) as well as spicy compounds than white oak1, whereas white oak offers considerably higher levels of oak lactones (ultimately yielding a coconut note to the flavor of the spirit) as well as vanillin3,5. Barrels from Japanese mizunara oak (Quercus mongolica) also have very high levels of vanillin and additional spicy compounds, yet are only used for the final stages of maturation (due to their delicate structure)2. Hybrid barrels, made up from different types of wood, are enabling interesting flavor combinations1. The Indian single malt whiskey Amrut Spectrum is matured in barrels made from American, Spanish and French oak as well as ex-Pedro-Ximenez- and ex-Olorosso-Sherry barrels. And with the Private Select from Maker’s Mark, customers can even select among 1001 possible stave combinations, made from five different types of wood.

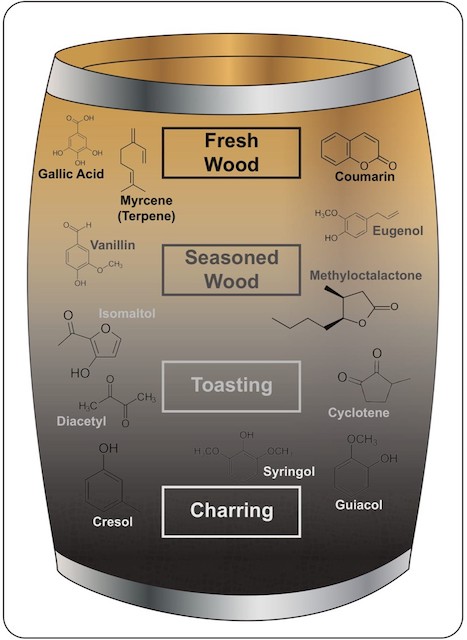

After choosing the wood, the next step is the so-called seasoning. Traditionally performed by air-drying to reduce the wood moisture (up to several years!), this process also mellows out some of the more herbaceous and resinous aromas3,5,6. Due to its higher tannin content, wood from European oak trees needs a longer seasoning period than wood from American oak1. During this process, rain water will hydrolyze and leach out astringent tannins as well as bitter coumarins, and natural microbial activity will produce increased amounts of eugenol (clove-like aroma), vanillin and methyloctalactone (the main coconut-like oak lactone)3,5. After assembling the barrels from the seasoned wood, the last step prior to the addition of the spirit is the toasting or charring of the barrel. During this process, the inside of the barrels will be incinerated for varying time periods, which exposes the wood to extremely high temperatures4. This not only changes the physical structure of the wood but also kickstarts a range of molecular changes7.

If you toast a barrel, only the upper wood layer will be changed. Yet after a certain level of charring, the so-called ‘alligator skin’ with a very rough, black and broken surface emerges4. Now physically, this opening-up allows the spirit to enter the wood through the porous structure and, next to enabling the liquid to pick up all those flavor molecules, the charred wood smoothes the flavor of the spirit by absorbing sulfuric compounds like an activated-carbon filter1. Some whiskey makers, such as most Tennessee whiskeys, do not take a risk and even pre-filter their spirits through charcoal before barrel-aging them8.

The high temperatures induced by toasting and charring complete the task of seasoning and degrade the remaining resin flavors (terpenes) and plank smells (long aldehydes)3,6. Additionally, the main constituents of wood, hemicellulose and lignin, are degraded which leads to a bountiful array of volatile aldehydes and ketones1,3,4,6,7,9. The most basic reaction is the generation of additional vanillin from degraded lignin, especially for American oak as in the case of bourbon1,10. In addition to vanilla, caramel flavors are introduced by the caramelization of sugars of the hemicellulose present in wood (producing the buttery diacetyl as a byproduct)1,4 as well as by volatile furfurals3,10. Other flavors including toasted almond/caramel (5-hydroxymethylfurfural), maple (cyclotene), cotton candy (maltol), freshly baked bread (isomaltol) and spiciness from phenolic aldehydes stemming from lignin contribute to the complexity3. Outright charring of the barrels creates increased amounts of syringol (smoky aroma), guiacol (smoky taste), 4-ethylguiacol (bacon aroma) and ultimately cresol (tar-like aroma)3,10 but also leads to the degradation of some of the subtle flavor molecules mentioned above3,9.

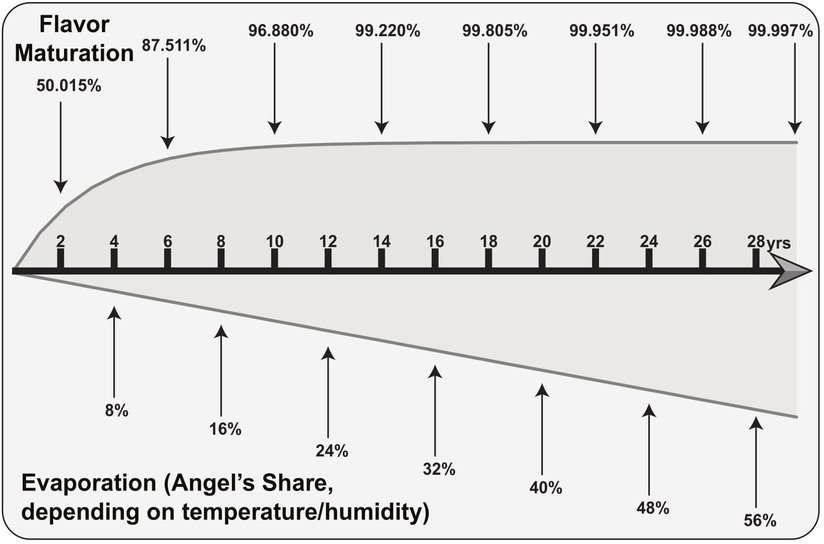

Once the spirit is added to the barrel, it starts to absorb all these molecules, gaining a darker color and a more complex aroma and taste1,3,5. This process is substantially faster in warm areas such as for Taiwanese whiskey than it is for scotch aged in Scotland1. Alcohol from the liquor will also start to react with fatty acids from the wood and create esters such as ethyl acetate (sweet and fruity aroma)11. But while there are attempts to speed up this year to decade-long process, such as by Orville Tyler by bombarding the freshly distilled liquor with ultrasonic sound to induce esterification processes, everything beginning from the choice of wood to the aging of the liquor in the barrel involves too many factors to fully recapture12. In fact, about one-third of the barrel-aging processes happen in the first year of aging and after 15 years of aging 99.5% are over13. To create a smooth and complex barrel-aged liquor, unwanted/harsh fermentation or distillation byproducts such as acetaldehyde, butyric acid or isopropanol need time to react with the wood or the alcohol12,13. But taking a sip of 15-year-old scotch will definitely remind you that the journey from fresh wood over toasted barrels up to a refined mixture of flavor molecules was absolutely worth it.

1) https://www.grapesandgrains.org/2017/05/the-influence-of-casks-and-science-of-whisky-aging.html

2) https://www.whiskyforeveryone.com/whisky_basics/influence_of_wood.html

3) https://winemakermag.com/1033-oak-barrel-chemistry-techniques

4) https://www.whisky.com/information/knowledge/production/background-knowledge/types-of-whisky-casks.html

5) https://www.scientificamerican.com/article/whiskey-makers-break-tradition-to-make-new-flavors/

6) https://winesnark.com/pass-the-toast-the-maillard-reaction-in-wine-barrel-toasting/

7) https://pubs.acs.org/doi/abs/10.1021/jf071665o

8) https://www.popsci.com/what-happens-in-whiskey-barrel-over-half-century

9) https://pubs.acs.org/doi/abs/10.1021/jf981234t

10) https://www.acs.org/content/dam/acsorg/events/culinary-chemistry/Slides/2013-06-13-barrels-wine.pdf

11) https://onlinelibrary.wiley.com/doi/10.1002/jib.165/pdf

12) https://www.popsci.com/technology/article/2011-12/scientific-ways-make-whiskey-taste-older-faster

13) https://www.shakestir.com/features/id/551/science-of-barrel-aging